- Via delle Tezze 64, 36070 Trissino, VI

- +39 0445 490381

- info@torneria2c.it

Torneria 2C management considers the customer satisfaction as primary target. The current market requires higher and higher attention to the product standards and the quality control objectives are of utmost importance. This implies a constant use of energy in the control of standards and in the search for continuous improvement, through new procedures, improvements, study of production cycles.

Our main effort is the achievement of the higher supply quality, the “tending to zero” defect rate; the care for particulars, having as target the reduction of production costs caused by low quality. All processing follows a procedure that involves an initial approvall, a check in production and a final check, before packaging.

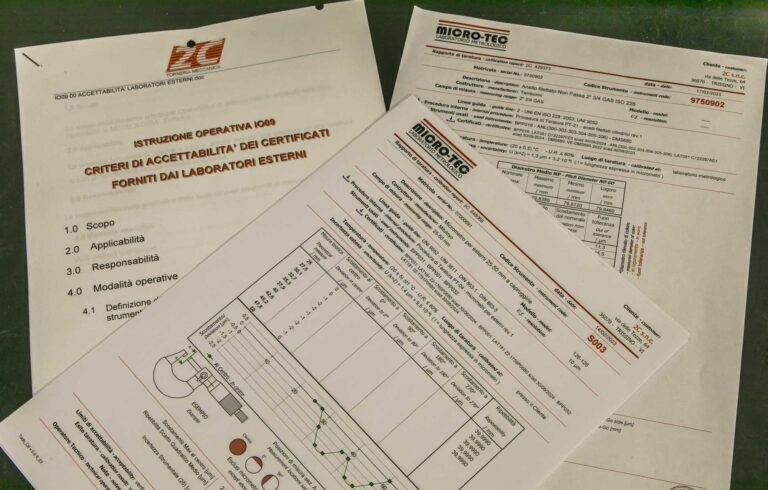

On demand, we can provide statistical analysis (cp-cpk), 100% control or non-destructive control in outsourcing with external laboratories.

Our quality department is provided with:

All instruments are certified and periodically calibrated by an external laboratory

Torneria 2C pays attention to the environmental sustainability.

Besides the UNI EN ISO 14001:2015 certification , some goals have been achieved; among others:

The following company policies have been issued and these certifications have been obtained:

The following projects have been completed:

“Studio e ricerca dell’ottimizzazione del processo di produzione aziendale, e sviluppo del prototipo di macchina a controllo numerico”

Automatic warehouse

CLEANING STATION KP 200 HMA

Via delle Tezze 64, 36070 Trissino, Vicenza

Phone +39 0445 490381

Fax: +39 0445 491163

Mail: info@torneria2c.it

P.IVA: 02078090244 — REA: VI 204425 — Cap. soc.: 15.600,00